Global plastic production is closely tied to the needs of the packaging industry. In an effort to protect natural resources, reduce waste, and limit human reliance on fossil fuels, packagers turn to various alternative materials that are not petroleum-based, like traditional plastic.

Global plastic production is closely tied to the needs of the packaging industry. In an effort to protect natural resources, reduce waste, and limit human reliance on fossil fuels, packagers turn to various alternative materials that are not petroleum-based, like traditional plastic.

These sustainably-sourced innovations account for an expanding share of the overall packaging market, appealing to eco-conscious consumers and contributing to greener packaging outcomes.

Experienced contract packaging companies operate on the cutting edge of sustainable packaging innovation, offering versatile packaging solutions that don’t rely on petroleum-based polymers.

Environmental Impacts of Plastic

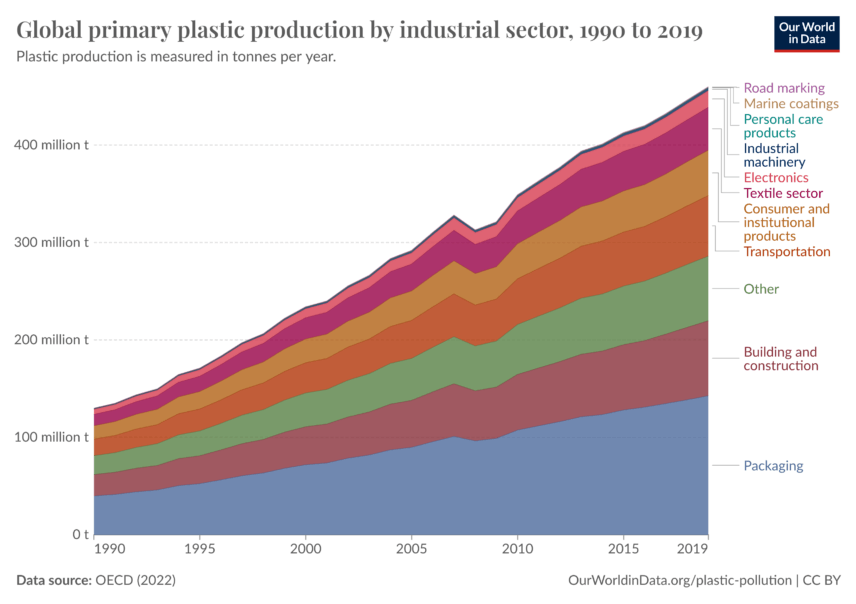

To say global plastic usage has risen dramatically since the first form of plastic was introduced in 1907 is an understatement. By 2010, annual plastic production had reached 270 metric tons, with plastic waste accounting for 275 metric tons (exceeding the annual production figure due to plastic waste from material produced in prior years). Since its introduction, more than 9.5 billion metric tons of plastic had been manufactured by 2019, representing at least 2200 pounds of plastic generated for each person alive at that time.

Among the distinct disadvantages of utilizing traditional plastics are that fossil fuels are depleted during the manufacturing process, and conventional plastic does not readily degrade. Plastic production itself pollutes the environment, and it is also thought conventional plastics take 500-1000 years to break down — during which the material releases harmful substances into the environment. Recycling eases the overall impact of plastic waste, but a relatively small percentage of plastic is ultimately recycled.

Although plastic is used in diverse applications across many global industries, plastic utilized for packaging accounts for more than 50 percent of total global plastic production, drastically outpacing construction, textiles, and other industries reliant on traditional petroleum-based plastics. Packaging production continues shifting toward greener packing alternatives with the effects of traditional petroleum-based plastic products stacking up against the environment and consumer sentiment embracing sustainability.

Materials innovation and commitments from manufacturers and packaging companies offer promising advances, mitigating the downsides of traditional plastic packaging. Among the new wave of ideas fueling greener outcomes, sustainable packaging alternatives are replacing conventional plastic in many cases, including shipping and packaging applications.

Bioplastics Facilitate Versatile and Sustainable Packaging Solutions

Sustainable plastic alternatives include bioplastics, which offer many qualities of petroleum-based plastic, with the added benefit of sustainable sourcing. Several forms of bioplastic are in use, contributing to greater environmental accountability, especially in the packaging industry, which relies heavily on the protective, durable features of plastic products. Single-use items, in particular, add volumes to the waste stream; bioplastic innovation presents opportunities to reduce pollution, without sacrificing consumer convenience and product integrity.

Various bioplastics serve as substitutes for petroleum-based plastic. Although they are derived from natural resources, bioplastics are not necessarily biodegradable. Care must be taken distinguishing how these substances are treated in the packaging waste stream. To be considered biodegradable, material must break down in a relatively short period of time, often limited to one year. To earn this distinction, bioplastics must degrade with the help of microorganisms such as bacteria and fungi, ultimately producing carbon dioxide, methane, biomass, and inorganic compounds.

Compostable bioplastics similarly degrade but decompose into nutrient-rich biomass that does not leave behind residue or toxins. Some compostable packaging alternatives can be processed at home, while others require special conditions offered only at specialized composting facilities.

Bio-based Sustainable Packaging Alternatives Gaining Momentum

- Starch-based plastic – Derived from corn starch, examples of starch-based bioplastic applications include compostable food and yard bags, as well as food packaging and disposable containers used in food service.

- Cellulose-based – In addition to eyeglass frames and other consumer goods, plastic applications with bioplastic derived from cellulose include thermoplastics and extruded films used in the packaging industry.

- Protein-based – Plant based packaging and animal protein-based materials provide workable plastic alternatives for the food packaging industry. Packaging companies utilize the eco-friendly approach, which relies on wheat gluten, casein, and milk to produce films and coatings for food packaging. Protein-based packaging protects freshness and food integrity without the downsides of petroleum-based plastics.

- Bio-derived polyethylene – Shipping and packaging material derived from sugarcane and corn has widespread applications within the packaging industry, including drums and bulk packaging, as well as crates, trays, bottles, and caps.

- Aliphatic polyesters – A group of bio-based polyesters that are suitable for replacing traditional plastics in some instances, aliphatic material includes polylactic acid (PLA), a form of recyclable and biodegradable polyester made from renewable sources. The material has applications across diverse manufacturing segments, including the packaging industry, where PLA serves as a sustainable alternative to traditional petroleum-based polymers.

Sustainable Paper and Cardboard Packaging Solutions Outperform Plastic

Recycling paper packaging into pulp and reusing the material to make new products is a relatively low-impact process, compared to creating post-consumer recycled plastics. Paper packaging can be recycled multiple times, helping paper packaging alternatives outperform even bioplastics, in terms of environmental sustainability.

Paper packages are derived from a renewable resource, and green paper manufacturing can be successfully undertaken with few or no chemical reactions, producing environmentally responsible recyclable or compostable paper packaging.

Paper packaging innovation includes versatile hot and cold food containers such as compostable clamshells, and even bubble wrap is no longer limited to plastic construction. Newly developed eco-friendly shipping materials such as paper bubble wrap get the job done without creating plastic waste. In addition to utilizing cardboard and paper to replace traditional plastic food containers and shipping components, contract packagers also offer paper-packaged alternatives in health, beauty, and other consumer segments.

Whether shifting toward bioplastics or embracing the benefits of paper packaging alternatives, established contract packagers maintain cutting-edge expertise in the growing sustainable packaging sector, an experienced packaging partner can help manufacturers reduce waste and negative environmental impacts during production and distribution, catering to the needs of modern eco-conscious consumers.

At Assemblies Unlimited, our innovation and resourcefulness can meet your packaging project needs. Whether you require a “plastic packaging alternative” solution or have other unique contract packaging requirements, please fill out the form to request a quote, and a packaging specialist will contact you to discuss your project.