Assemblies Unlimited has the expertise and knowledge to manage your complete skin packaging project from start to finish. All you need to do is supply us with the product and artwork and we can do the rest.

Skin packaging is a lower cost packaging option for a retail product and should be considered for products with low price point and/or higher production runs. It is also best suited for smaller products that are relatively lightweight but can be used for larger items as well.

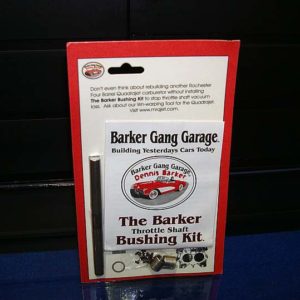

A Mylar ’skin’ is sucked over your product while securing itself to a skin card. This transparent film allows full view of your product while acting as a tamper resistant coating to secure your product. It is a popular packaging method for retail and can help promote your product effectively with the proper design and colorful graphics.

Features and design parameters to consider for Skin Packaging:

- Skin Card Size: You always want your skin card to be as small as possible as it will play a “cost” role in the sealing and die-cutting part of the assembly process. Standard thickness for a skin card is .024 point.

- Hang Hole: Most every skin card should have a die-cut hang hole. This is NOT an additional cost yet is required by most retailers.

- Minimum Production Runs: Our minimum run for skin packaging is 10K units.

- Artwork: All artwork is to be supplied by the customer. We can suggest a local graphic designer upon request. Art can be emailed, supplied on an electronic disk or uploaded to our FTP site. All art files should be supplied in high resolution Adobe Illustrator (.ai) file format with unlocked layers.

- Final Pack-Out Options: Once your product is skin packaged let us know how you want it packed into cartons and how many per carton. Final pack-out options include: master cartons (shippers), counter displays, POP displays, sidekick displays, PDQ displays, or club pack displays. We can help you determine the best option for your specific product.

- Timelines & Lead-Times: Once you have selected a skin card size and all of your artwork is completed we can prepare proofs for you to approve. After final proof approval we can begin your skin packaging assembly project in approximately 2 weeks and have finished goods ready to ship for you in 3 weeks. Tell us what your delivery requirements are and we will find a way to make it happen.