We can provide all types of labeling as well as re-labeling solutions for you, including:

- Pressure sensitive (all types and sizes)

- Full Body shrink sleeves (using steam tunnel technology)

- Glued labels for Aluminum cans (remove and relabel automatically with glued labels, sizes: 201, 211, 300, 301, 303 and 401)

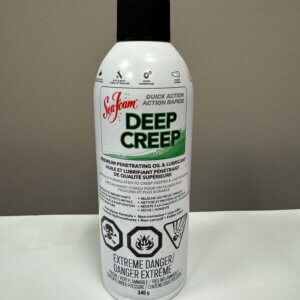

- Aerosol cans

- Tipping (applying promotional coupons or give-aways to literature automatically)

- Manual application of labels to pouches, bottles, boxes and more…

Shrink sleeves, shrink bands, and as well as neck bands for tamper evidence have all experienced growth due to the ongoing driver to innovate by the CPG companies with containers and closures as companies look for better and more clever ways to build their brand.

Popularity in the Dietary Supplement space has also contributed with the explosion of larger canisters housing muscle enhancers such as Whey Protein. These containers require unique labeling applications including full wrap-around PS labels, full body shrink sleeves, neck bands and more.

With our turnkey services, Assemblies Unlimited will work with you and help you determine precisely what your labeling needs are, based on your container. In addition, we will source the required labels locally, apply the labels and then manage the whole project, which will save you money.

We have experience in all label technologies for contract packaging and have the preferred label printers who can supply us with quality labels or sleeves quickly so to help meet aggressive timelines for your labeling or relabeling project. Supply us with your artwork and the containers to be labeled, and Assemblies Unlimited will do the rest.

- We provide quick turnaround, broad capability, and multiple labeling locations. When considering your next labeling requirement, provide us with your container samples along with the following data for the most accurate quote:

- What is the size of the label you require?

- What is the material of your label? Ex: Paper, PET, laminated, chemical resistant, PE, Mylar?

- How many colors do you want to have printed on your label? (4 colors process is the least expensive)

- In the case of a PS (pressure sensitive), are you looking for a full wrap-around label that touches or do you want a gap where they meet?

- For a full body sleeve or a shrink sleeve, do you require a steam tunnel to ensure uniformity, or would a regular convection shrink tunnel be sufficient? (Hint: Using a more traditional heat tunnel would be less than using a steam tunnel)

- What volume production run are you considering?

- What is your expected volume for the first 12 months?

- What is it that you are labeling? (Ex: Glass of plastic bottle, flexible pouch, aluminum can, aerosol can, etc)