If you are looking to outsource the contract filling or contract packaging of a food-grade powder, solid or liquid, contact Assemblies Unlimited. Since 1993, we have experience in managing food packaging projects from beginning to end, including full turnkey sourcing and procurement of all the raw packaging materials.

We have had huge success in helping customers who are looking for primary and secondary contract packaging for powders, solids, and liquids or beverages in all types of containers, including stand-up pouches, zipper pouches, gusseted pouches, Sachets, rigid containers, sift-proof cartons, PET or HDPE bottles, tubes and more.

Food Packaging Solutions

For dry powder filling, we can also source the ingredients and do the contract blending upon request. Some of the types of custom packaging solutions we can provide for both wet and dry food are the following:

- Powdered drink mixes

- Cake, Brownie, and Soup mixes

- Spices

- Sugar

- Salt blends

- Dairy creamers and Seasonings

- Trail mixes

- Dried Fruits & Nuts

- Gummy Bears

- Pasta and Rice

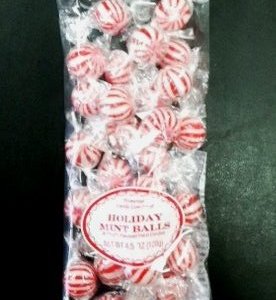

- Hard Candies

- Coffee and Teas

- Confectionary

- Coconut oil

- Fish oils

- Cereals

- Dietary Supplements

Assemblies Unlimited can provide you with raw packaging materials, including flexible film, chipboard retail cartons, pre-made stand-up pouches, roll stock, counter displays, corrugated shippers, and more, through local partners who help reduce shipping costs.

Our experienced design team can guarantee that the right material will be specified for the right packaging machine, which helps avoid costly errors. We will help select the proper film construction for your product to maximize shelf life and production efficiencies.

Contract Filling Solutions

- Pouching (dry)

- Pouching (liquid)

- Club Packs

- Bottle Filling

- Stick Packaging

- Cartoning

- Seasonal Gift Sets

- Vertical Form, Fill & Seal (VFFS)

- Horizontal Pouching

- Secondary Packaging

- Bag in Box

- 2 Stage Fill

- Blending

- Tube Filling

Features and Design Parameters to Consider for Food Packaging Projects

- Size – What are the outer pouch or carton dimensions?

- Material Specifications – What film construction or carton specifications do you require? Raw Ingredients: We require that ALL raw food ingredients are supplied by our customers.

- Minimum Production Runs – Our minimum production run is based on the size and overall scope of your project, but our typical minimum runs are 50K-100K units

- Artwork – All artwork is to be supplied by our customer. Art can be provided on a disk, emailed, or uploaded to our FTP site. All art files should be in high-resolution Adobe Illustrator (.ai) format.

- Final Pack-Out Options – Once your product is packaged, how do you want it packed for shipping? Choices are master cartons (shippers), counter displays, POP displays, sidekick displays, PDQ displays, or club pack displays. We can help you determine the best option for your specific product.

- Timelines & Lead-Times – Once sized, material and pack-out specifications are finalized, we can begin production. We are willing to do whatever it takes to meet any tight completion deadlines you may have.