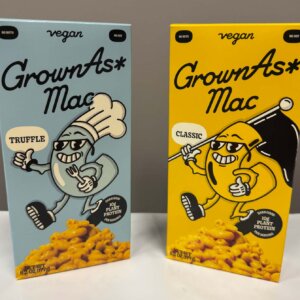

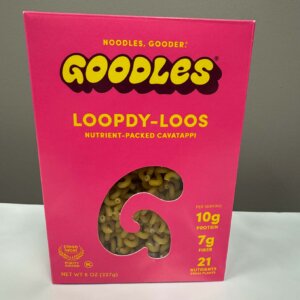

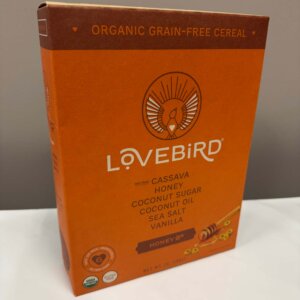

Bag-in-box refers to a retail carton that has a filled pouch or “bag” inside of it. Bag-in-Box applications are used for powders as well as liquids. Examples of powder Bag in Box can be Cereals, Mac N Cheese, cake mixes, soup mixes and pancake mixes. Bag in box for powders refers to a dry blend that is first weigh-filled from a vertical form fill and seal machine into a pouch and sealed. The pouch is then inserted into a printed retail box for presentation on the store shelf.

Assemblies Unlimited can provide you with a cost-effective Bag-in-Box solution by completing both packaging steps of pouching and cartoning on the same production line. A fully automated solution would allow the powder blend to be vertically filled into a pouch and then that pouch be automatically inserted into the box on a cartoning line. We have multiple high speed lines for your custom project and if additional machinery or tooling is required we will invest in the partnership and come up with an automated line for your product.

Assemblies Unlimited has a deep expertise with several large CPG companies for Cereal packaging and Mac N Cheese packaging. If you are looking for a cost-effective and fully automated solution for a Bag-In-Box project, please contact us immediately at 1-877-273-6259.

Packaging specifications needed to receive a quote on Bag-In-Box:

- Size of bag

- Size of box

- Fill weight of bag

- Structure of film for bag (moisture, air or odor barriers)

- Lot/date coding requirements

- Number of colors for printing bag / box

- Type of box seal required (glue flaps both ends is standard)

- How finished retail box gets packed out for shipping

- Markings / labels required on master case

- Quantity per production run (25K unit minimum)